3 Simple Techniques For Crossdock Warehouse

Wiki Article

The Single Strategy To Use For Sacramento Cross Dock

Table of ContentsHow Crossdock Warehouse can Save You Time, Stress, and Money.Excitement About Crossdock WarehouseThe Single Strategy To Use For Sacramento Crossdock WarehousingThe Main Principles Of Sacramento Crossdock Warehousing The Sacramento Crossdock Warehousing IdeasThe Facts About Sacramento Crossdock Warehousing Uncovered

By setting and achieving storage facility objectives, a business can boost its overall operations as well as lower line. What are some objectives for storehouses and exactly how do they help with service method?It is essential to keep in mind that the goals remain in dispute with business critical purposes. A Puerto Rico grocery store chain bought paper products from a storage facility loaded with products to conserve cash on delivery. Storehouse workers required that shop managers discount paper items in order to satisfy transport objectives.

The objective of the warehouse supervisor was to raise performance, asset utilization, and customer satisfaction. The finance organization remained in arrangement with him because they both had comparable company cash-flow objectives. If objectives were aligned, there would certainly be no demand for continuous opinion in between managers. Supervisors may need to reset warehouse goals in order for the whole supply chain team to accomplish corporate goals.

The 6-Minute Rule for Sacramento Crossdock Warehousing

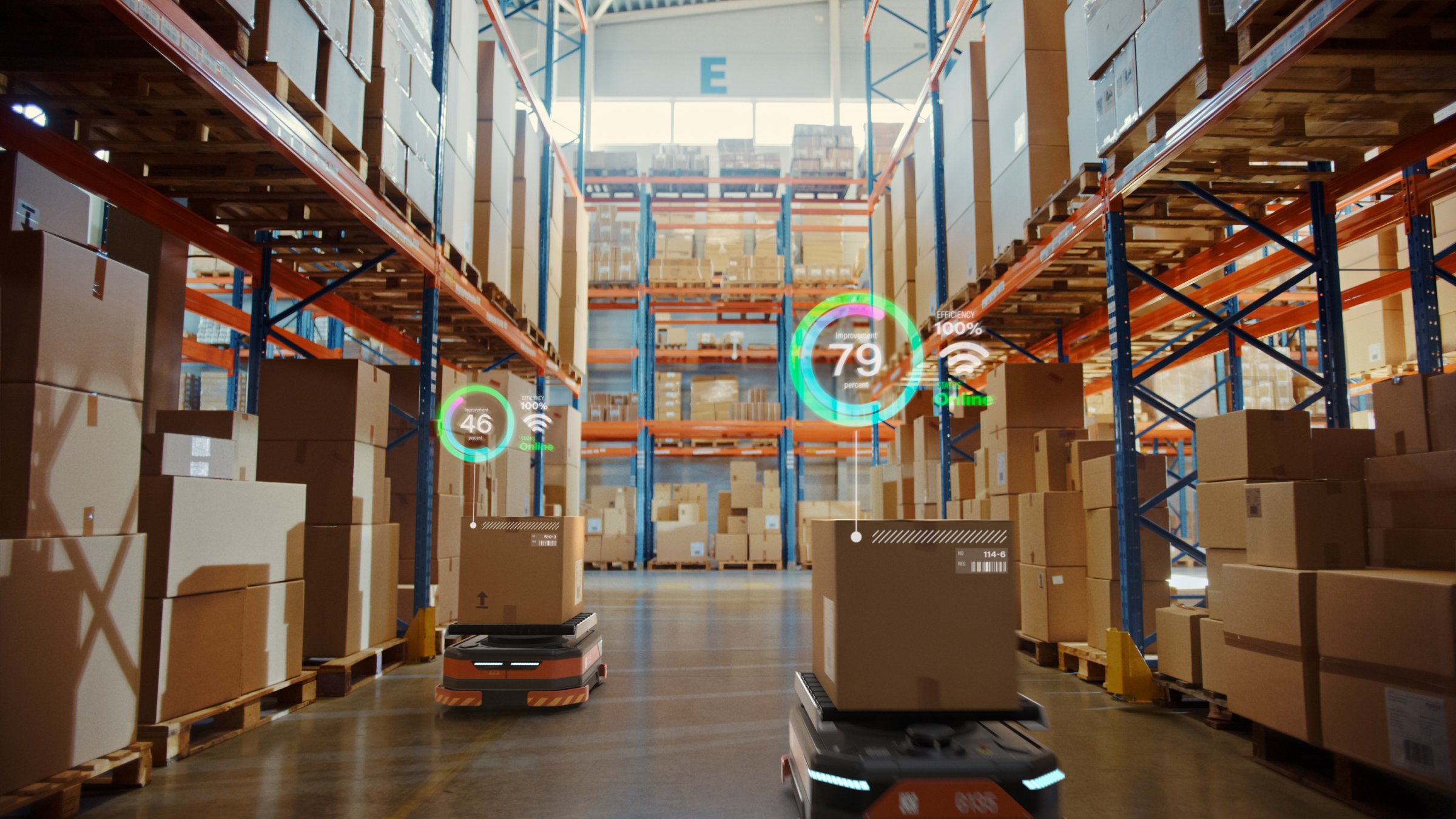

Supply chains can efficiently manage their inventory and also gratification services with cloud-based warehouse administration systems. In the instance of third-party logistics, the supply chain is generally used along with stockroom monitoring systems. Having a robust system can enable stockroom managers to keep whatever on course as well as simplify their operations.Picking lists for the function of recouping items a lot more successfully should be applied in stockrooms. To function correctly, storage facility procedures need to be able to receive stock or freight from providers when loading docks are open. Every box and item in a box need to be checked by a storage facility administration system.

In a current storage facility instance study, it was revealed that by utilizing a much more reliable storage system, the company was able to enhance its profits by 15%. This was achieved by minimizing the amount of time required to discover and obtain supply, as well as decreasing the amount of labor called for to keep the storehouse arranged. Sacramento Warehouse.

The Basic Principles Of Sacramento Cross Dock

Warehousing and tasks, which are usually described as "transport at zero miles per hr," take around 20% of total logistics circulation expenses; consequently, they urge logistics executives to provide them significant factor to consider. Warehousing is typically used at two factors in the logistics chain. Raw products (such as coal, iron, ore, steel, gold ore, or sugar cane) might be stored in a storehouse prior to they are refined in a factory; they may also be stored as finished items after they have actually been refined.An appropriate definition of warehousing after that would be: Warehousing is a system of storing items en route from their point of beginning (as raw materials) to their factor of usage (as finished items). Because need for items can not be anticipated with assurance as well as they can not be provided promptly, storing supplies is unpreventable.

A lean system is when an organization chooses to have a minimum quantity of stock accessible to keep the cost sites of stock and warehousing fairly low. A business with a lean inventory system only purchases materials or relocations product when there is need from a customer. Lean stocks typically mean that the price of resources, warehousing as well as inventory administration is lower than other systems.

Not known Factual Statements About Sacramento Warehouse

When stock information is imprecise, you may buy a too much or insufficient amount of basic materials required for production or overproduce goods when it is not needed. When stock levels obtain low in a storage facility, the majority of companies would normally send out more item. With no effective system in location for inventory, some companies may miss the mark as well as sustain unneeded warehousing expenses.

You would certainly also be happy to listen to that there are aerial work systems offer for sale out there that would allow you to do tiny, tool, or huge load training in your storehouse. It even more makes the supply monitoring procedure more reliable. Warehousing is optimal for services attempting to get more organised and also match supply with demand.

As a component of SCM, efficient stock administration might lead to a more powerful supply chain. One more reason great warehousing is important to SCM is that it provides a method for companies to make sure the availability of the best products at the right location whenever the time is. It increases the utility worth of the products that method.

Get This Report on Sacramento Cross Dock

Customers expect to understand when about their purchases will be supplied after an order is positioned. The expertise regarding the shipment time enhances their self-confidence. A few of them pay quicker because of this. Obviously, they become a lot more reluctant when uncertainty exists around the prompt shipment of items. Nowadays, delivery speed seems to be one of the substantial elements that consumers think about when choosing an item as well advice as choosing whether or not to continue with the acquisition.

A significant factor to invest in developing a warehouse is the several known economic benefits that come with it. Not only the enhanced efficiency of the supply chain but also the storage facility's storage capacity as well as exactly Read More Here how it acts as a central location for your items add to its economic benefits.

These points can be seen or know with combination and also accumulation operations. Here's a more detailed take a look at how consolidation and accumulation can assist lower prices: With consolidation operations, there's no requirement to deliver products separately from several resources because they can be provided to your stockroom as supplies. As soon as an order is put, you or your staff can load and also ship the product out from there.

Sacramento Crossdock Can Be Fun For Anyone

Not just that, but excellent warehousing additionally enhances client service and uses economic benefits. All of these things might cause higher income as well as boosted company profitability.Report this wiki page